The European project PERKS has started, coordinated by Cefriel with the involvement of eight partners at European level. It will improve industrial operational efficiency through the use of AI for a more efficient and effective management of procedural knowledge for people

Optimizing knowledge management to enable Industry 5.0. This is the important objective of the three-year European project PERKS, recently launched and co-financed by the Horizon Europe Programme, as part of the “Digital, Industry and Space” Cluster.

PERKS will use Artificial Intelligence to provide digital support dedicated to industry operators in the creation, use and governance of procedural knowledge, i.e. the set of skills, information and experiences relating to “know-how” in industrial processes. “In addition to AI and data – states Irene Celino, Head of Knowledge Technologies Unit in Cefriel and PERKS Coordinator – the project puts people at the center, in alignment to the Industry 5.0 paradigm. All project activities aim to address the concrete needs of industry workers by providing AI-based digital tools to carrying out their activities better and more easily”.

The project has a budget of around 3.5 million and funding of around 2.9 million euros and will be coordinated by Cefriel in collaboration with a team of eight European partners (DFKI, Fagor Automation, IDC, NTT DATA, Onlim, Siemens, Whirlpool, Wirtschaftsuniversität Wien).

What are the use cases?

Procedural knowledge in industry takes very different forms: processes, regulations, guidelines, instructions, norms, good practices, etc. To ensure flexible solutions for various contexts, PERKS will address three industrial scenarios with different needs and complexity: safety procedures for maintenance interventions on household appliance production plants; configuration instructions for computer numerical controlled machines (CNC) in industrial systems; guidelines for optimizing energy consumption in microgrids and energy communities. PERKS impact will be assessed through the measurement of appropriate indicators, both operational and technical, and in terms of business and sustainability results.

What are the concrete expected results?

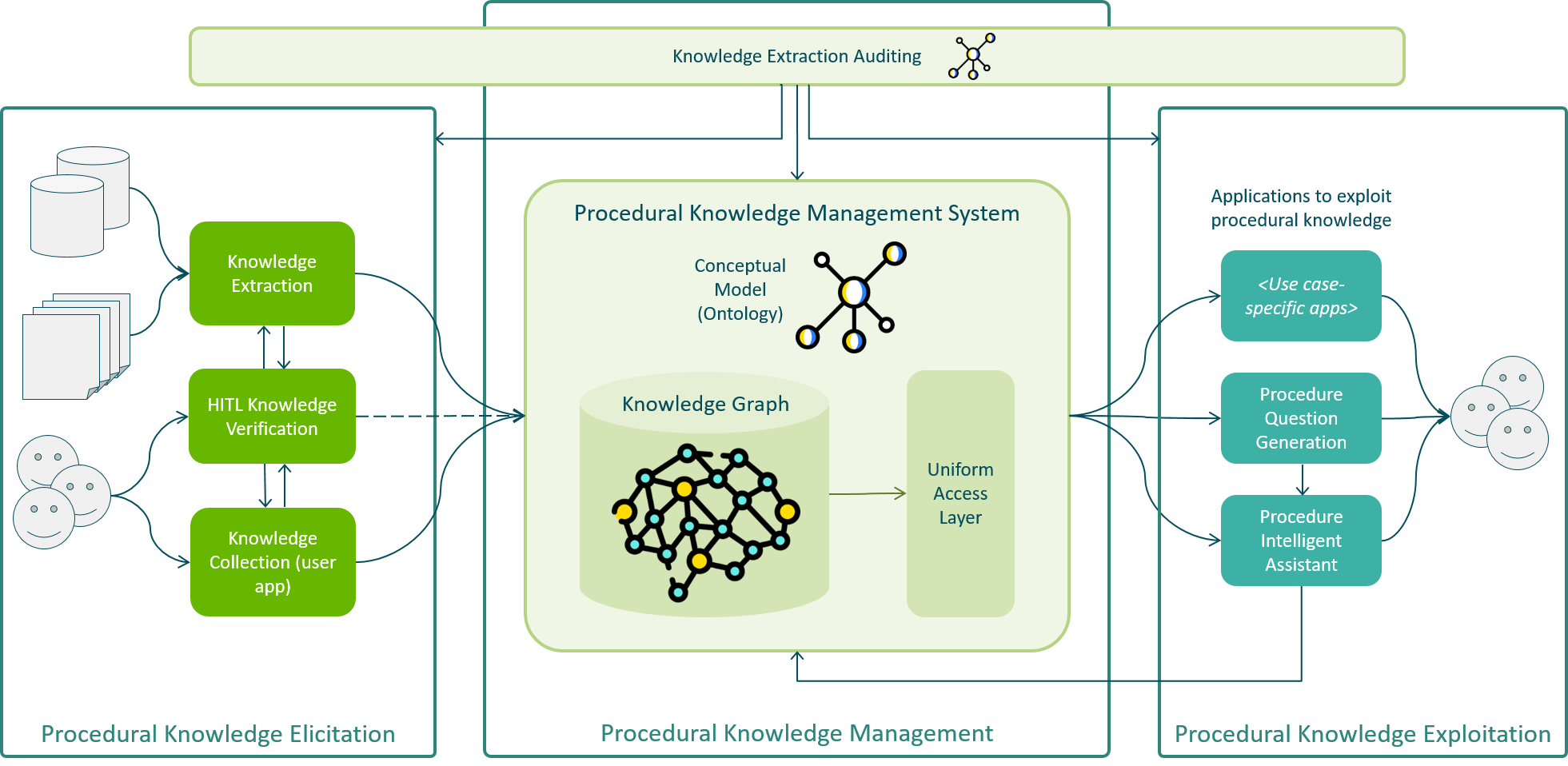

In addition to specific integrated solutions to solve the mentioned use cases’ challenges, PERKS aims to provide a set of modular, interoperable and complementary digital tools that can be composed and customized according to specific needs: in fact, by putting people and their needs at the center, PERKS aims to develop a set of methodologies and best practices for a wider application of AI and data in other industrial contexts, ensuring broad transferability of results.

What are the industrial impacts?

The first target of PERKS results are industry workers who, supported by innovative digital tools, will be able to collect, retrieve and carry out procedures in a more efficient and effective way. This will lead to a higher operational standardization which will allow a reduction in costs, errors and disruptions. The indirect economic impacts will be considerable, such as the increase in worker productivity and satisfaction, the skill development and enhancement in the community of professionals, with a simplified transfer of knowledge between people, the improved risk assessment and the reduction of accidents and errors in industry.